Concrete filled steel tubular (CFST)

By leveraging the merits of both structural steel and concrete, CFST columns offer excellent structural and economic benefits compared to steel and concrete counterparts. Therefore, they have been widely used in many civil engineering applications as a structural member under compression such as columns in tall buildings, towers in bridges and primary load-bearing members in large infrastructure. The use of high strength materials in CFST members not only reduces column sizes and consequently generates more valuable workspace for commercial use, but also provides sustainability benefits by reducing the use of construction materials. Therefore, the research of our group focuses on promoting the use of high strength CFST columns in composite construction. Most of this research have been done in collaboration with Professor Brian Uy’s team at The University of Sydney under ARC projects (DP120101944, DE140100747, DP170100001, FT200100024). Notable contributions of our work in this topic include:

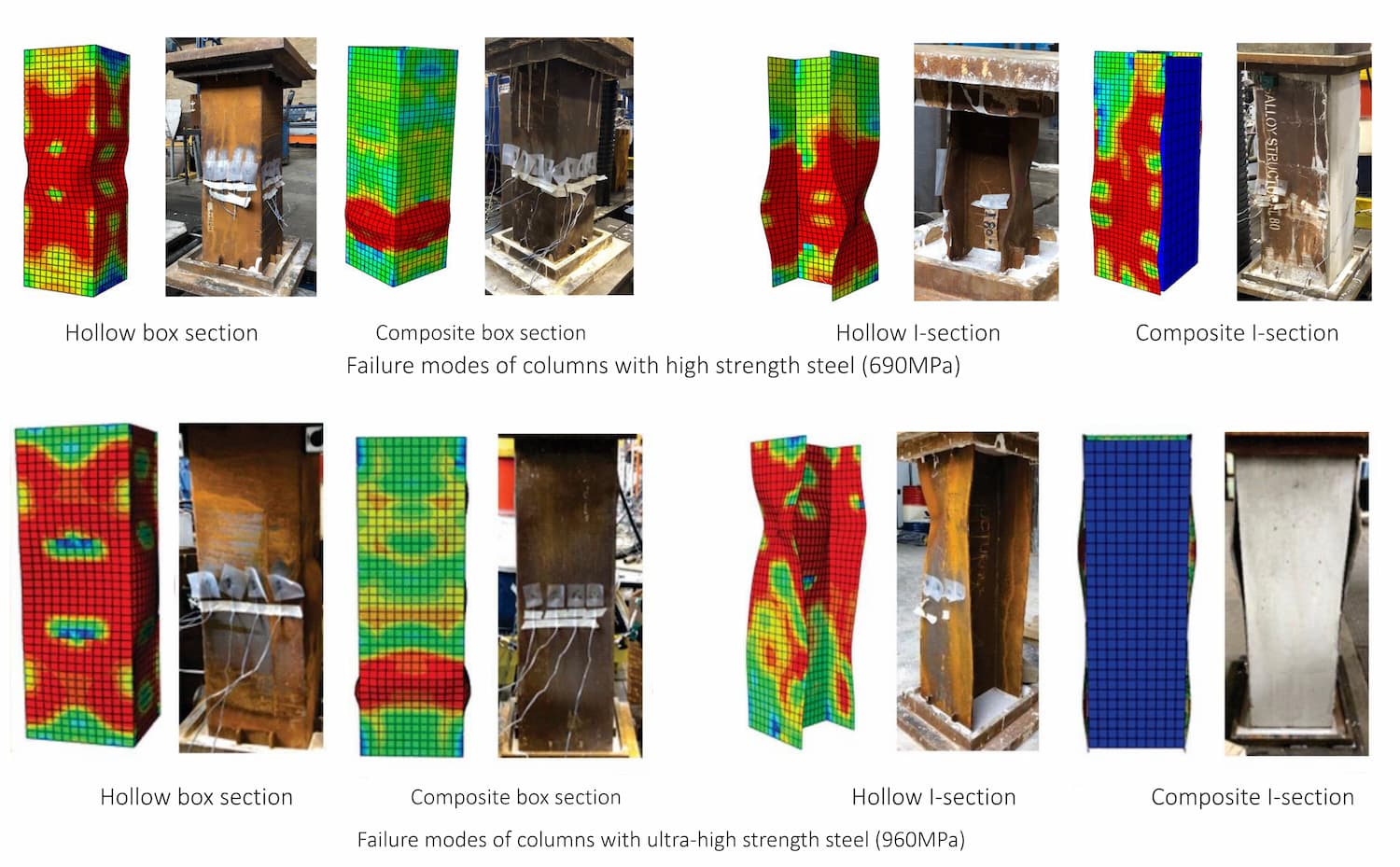

(i) Local buckling slenderness limits for high strength steel

We examine whether the current slenderness limit for normal steel is applicable for high strength steel or not. Two series of tests with a total 32 specimens of columns with box and I-sections have been tested (see below figures for typical failure modes). Both high strength steel (BISALLOY 80 steel with nominal yield stress of 690 MPa) [1] and ultra-high strength steel (with nominal yield stress of 960 MPa) [2] were considered. New slenderness limits have also been proposed for high strength and ultra-high strength steel and composite columns based on the experimental and numerical results.

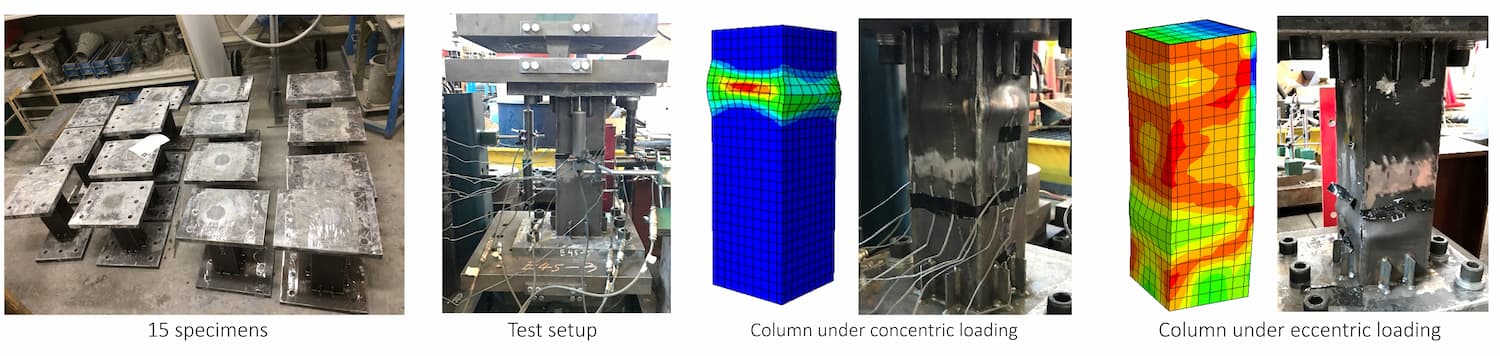

(ii) Design of CFST columns with the strength and section slenderness beyond permitted limits

Most of the current design codes of practice are only applicable for CFST columns with normal strength of steel and concrete (except for ASNZS 2327 which allows for the use of high strength steel with fy up to 690 MPa and high strength concrete with f'c up to 120 MPa). This study has therefore looked at the design of CFST columns with the material strength and section slenderness beyond the permitted limits. Two series of tests with a total 15 specimens of high strength columns were tested under concentric loading [3] and eccentric loading [4]. High strength Q&T 80 steel with the nominal yield stress of 690MPa and high strength concrete (Grade 150MPa) were used in CFST columns with different slenderness (compact, non-compact and slender sections). Design guidelines for CFST columns with slender sections and high strength materials were also proposed [3-5]. We also calibrated the reliability of current design codes [6] and explored their applicability in design the CFST columns having the strength and section slenderness beyond the permitted limits [7]. For this reason, we have collected a database of over 3,200 tests of CFST structures which can be found on Mendeley Data via this link https://doi.org/10.17632/j3f5cx9yjh.1

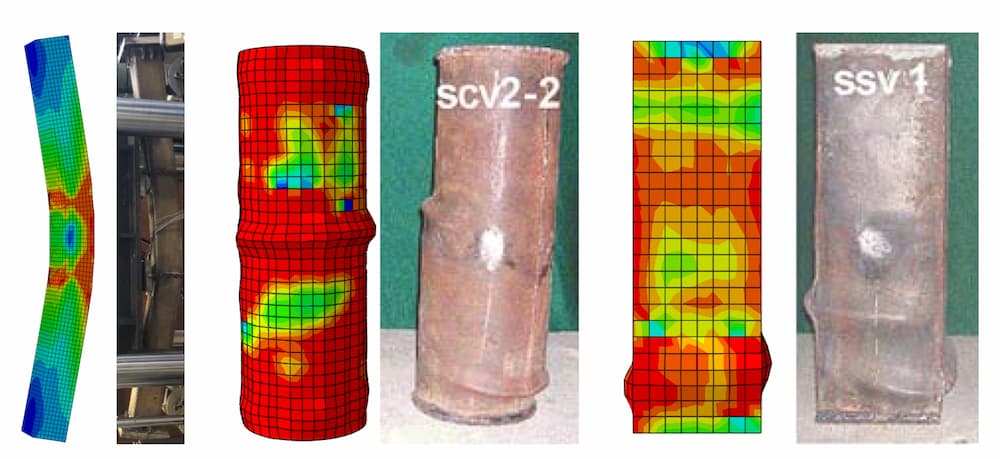

(iii) Numerical Modelling

We have developed several numerical models to predict the behaviour of high strength CFST columns ABAQUS [8-11] (see figure below), self-developed fibre force-based beam element that can accounts for local buckling of steel tubes [12], and self-developed fibre hinge displacement-based beam element [13]. We also developed analytical models that can be used for preliminary design purposes [10, 11, 14, 15].

Projects for Prospective PhD Students

We are currently looking for a PhD student to work on the fire performance of high strength CFST columns.

References

[1] Huang Z, Li D, Uy B, Thai HT, Hou C. Local and post-local buckling of fabricated high-strength steel and composite columns. Journal of Constructional Steel Research 2019;154:235-249.

[2] Li D, Huang Z, Uy B, Thai HT, Hou C. Slenderness limits for fabricated S960 ultra-high-strength steel and composite columns. Journal of Constructional Steel Research 2019;159:109-121.

[3] Nguyen TT, Thai HT, Ngo T, Uy B, Li D. Behaviour and design of high strength CFST columns with slender sections. Journal of Constructional Steel Research 2021;182:106645.

[4] Nguyen TT, Thai HT, Li D, Wang J, Uy B, Ngo T. Behaviour and design of eccentrically loaded CFST columns with high strength materials and slender sections. Journal of Constructional Steel Research 2022;188:107004.

[5] Zarringol M, Thai HT, Ngo T, Patel V. Behaviour and design calculations of rectangular CFST beam-columns with slender sections. Engineering Structures 2020;222:111142.

[6] Thai HT, Thai S, Ngo T, Uy B, Kang W-H, Hicks SJ. Reliability considerations of modern design codes for CFST columns. Journal of Constructional Steel Research 2021;177:106482.

[7] Thai S, Thai HT, Uy B, Ngo T. Concrete-filled steel tubular columns: Test database, design and calibration. Journal of Constructional Steel Research 2019;157:161-181.

[8] Thai HT, Uy B, Khan M, Tao Z, Mashiri F. Numerical modelling of concrete-filled steel box columns incorporating high strength materials. Journal of Constructional Steel Research 2014;102:256-265.

[9] Hassanein MF, Patel VI, Elchalakani M, Thai HT. Finite element analysis of large diameter high strength octagonal CFST short columns. Thin-Walled Structures 2018;123:467-482.

[10] Patel VI, Hassanein MF, Thai HT, Abadi HA, Paton-Cole V. Behaviour of axially loaded circular concrete-filled bimetallic stainless-carbon steel tubular short columns. Engineering Structures 2017;147:583-597.

[11] Patel VI, Hassanein MF, Thai HT, Al Abadi H, Elchalakani M, Bai Y. Ultra-high strength circular short CFST columns: Axisymmetric analysis, behaviour and design. Engineering Structures 2019;179:268-283.

[12] Thai HT, Uy B, Khan M. A modified stress-strain model accounting for the local buckling of thin-walled stub columns under axial compression. Journal of Constructional Steel Research 2015;111:57-69.

[13] Thai HT, Kim SE. Nonlinear inelastic analysis of concrete-filled steel tubular frames. Journal of Constructional Steel Research 2011;67:1797-1805.

[14] Phan DHH, Patel VI, Liang QQ, Al Abadi H, Thai HT. Simulation of uniaxially compressed square ultra-high-strength concrete-filled steel tubular slender beam-columns Engineering Structures 2021;232:111795.

[15] Phan DHH, Patel VI, Al Abadi H, Thai HT. Analysis and design of eccentrically compressed ultra-high-strength slender CFST circular columns. Structures 2020;27:2481-2499.