CFST column-to-beam joints

This topic was carried out under the support of an ARC DECRA Fellowship grant (DE140100747). Composite columns in the form of concrete-filled steel tubular sections have been increasingly used in composite tall buildings due to their structural and economic benefits. This project will therefore develop innovative joining technique to connect CFST columns to composite beams in composite buildings using blind bolts which can be installed from the outside of hollow sections. A comprehensive research program including experimental testing, numerical investigation, and design code development, has been carried out as summarized as follows.

Experimentation

Four specimens of composite joints with different types of column sections (square and circular) and endplates (flush and extended) have been tested to examine their behaviour under static loading. It was found that the joint behaved in a semi-rigid manner and its rotational capacity exceeded the ductile requirement [1].

Numerical Modelling

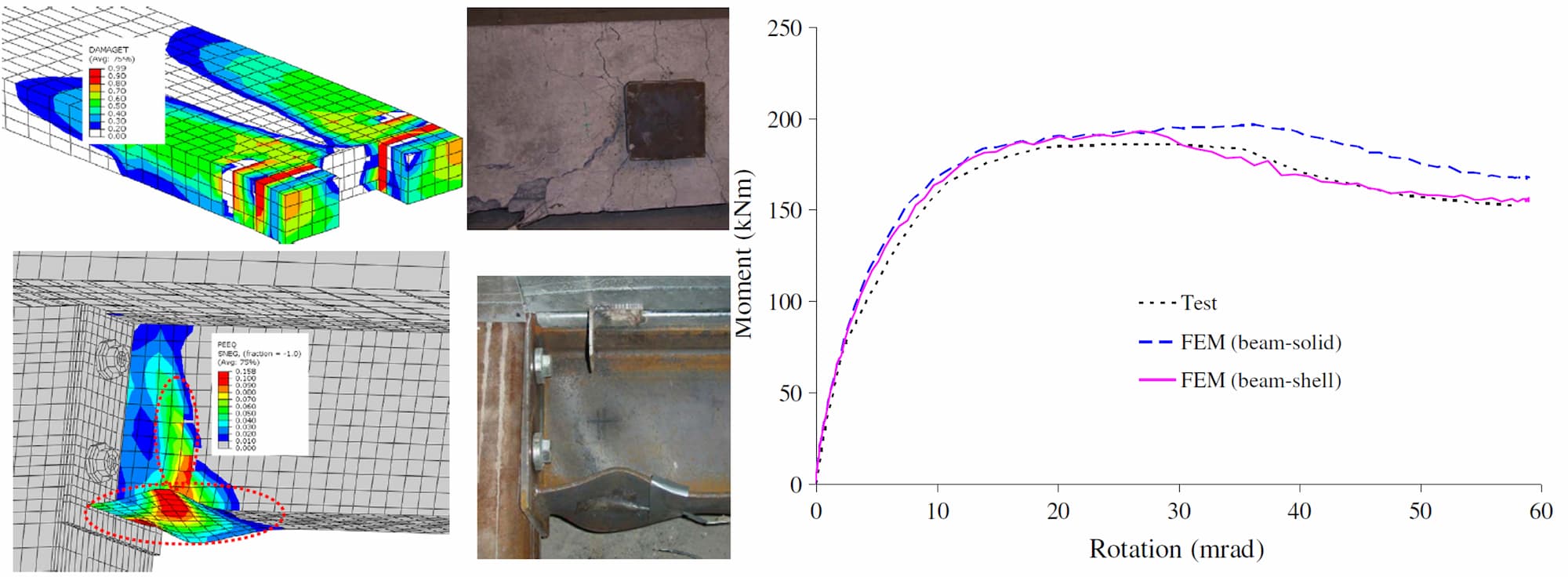

Detailed finite element (FE) model has been developed and validated against the experimental results [2]. The FE model can capture well both the moment-rotation behaviour and failure modes (e.g., buckling of steel beam, crack in concrete slab, etc.). It has therefore been used to examine the effect of various geometric and material parameters on the behaviour of connections to provide useful information for the development of design guidelines.

Design Code Development

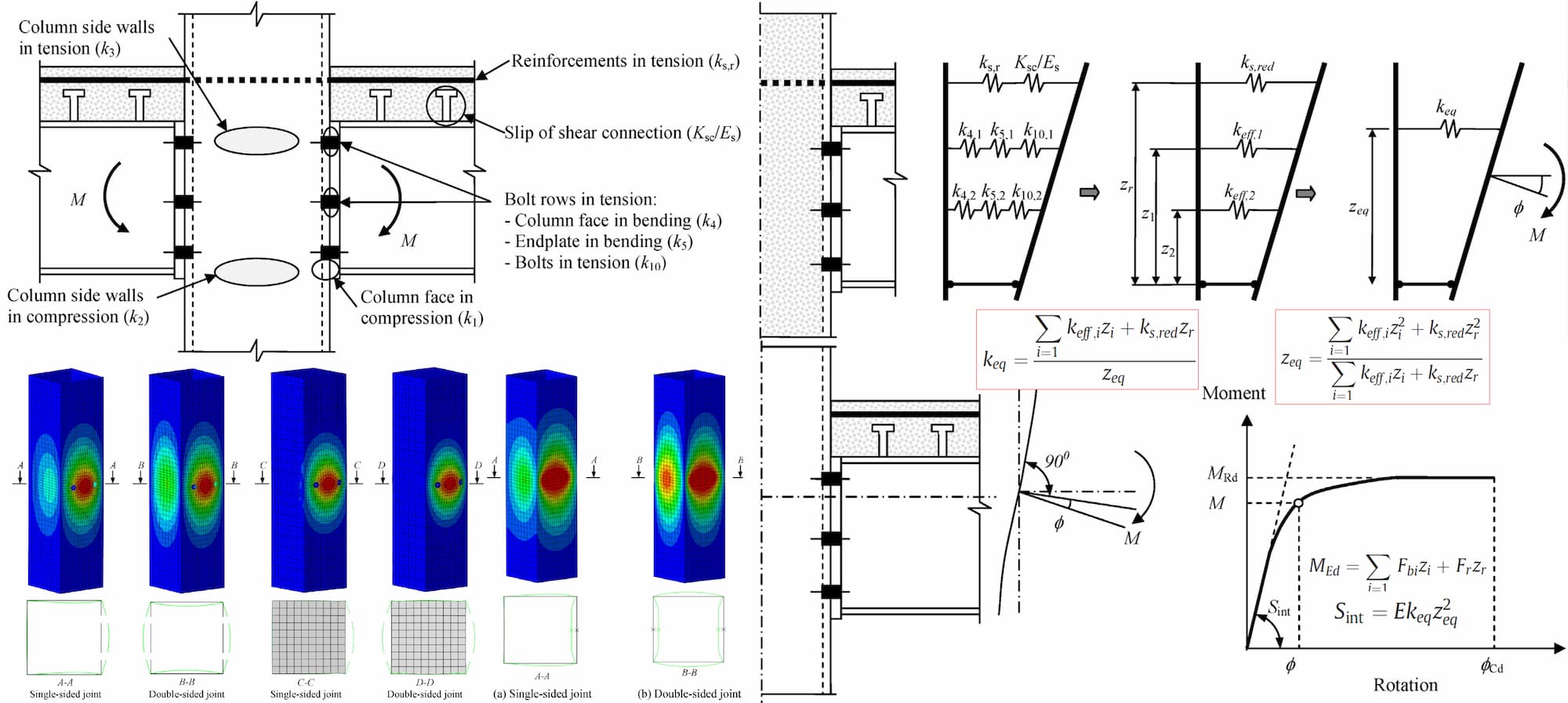

Based on the experimental and numerical results, design guidelines for composite joints have been developed [3] based on the concept of the component method adopted in Eurocode 4. These guidelines were implemented in the composite standard ASNZS 2327 (Section 5 – Design of Composite Joints).

Further study of this composite joint was also conducted to examine its behaviour under cyclic loading [4] (with the support from ARC Linkage Project (LP110200511)) and its demountability [5] (with the support from ARC Discovery Project (DP140102134)) in collaboration with Professor Brian Uy at The University of Sydney.

References

[1] Thai HT, Uy B, Yamesri, Aslani F. Behaviour of bolted endplate composite joints to square and circular CFST columns. Journal of Constructional Steel Research 2017;131:68-82.

[2] Thai HT, Uy B. Finite element modelling of blind bolted composite joints. Journal of Constructional Steel Research 2015;112:339-353.

[3] Thai HT, Uy B. Rotational stiffness and moment resistance of bolted endplate joints with hollow or CFST columns. Journal of Constructional Steel Research 2016;126:139-152.

[4] Waqas R, Uy B, Thai HT. Experimental and numerical behaviour of blind bolted flush endplate composite connections. Journal of Constructional Steel Research 2019;153:179-195.

[5] Wang J, Uy B, Thai HT, Li D. Behaviour and design of demountable beam-to-column composite bolted joints with extended end-plates. Journal of Constructional Steel Research 2018;144:221-235.