Durability of materials for construction

We assess and estimate service life of new materials for construction.

Because knowing the ability of a new material to withstand the conditions for which it is designed without deterioration for a long period of years is the only pass way to increase trust and take these materials outside the lab.

Our laboratory is well equipped to estimate the durability of material for constructions. We’ve developed tools and procedures to assess life span of new materials for construction. We can define the ability of material to resist to:

- Weathering action (humidity, cold temperature, dry, sea side …)

- Chemical attack (sewage, corrosion, carbonation …)

Durability properties are dependant upon many parameters, from early-age properties of concrete to the pursuit of high-performance civil engineering application.

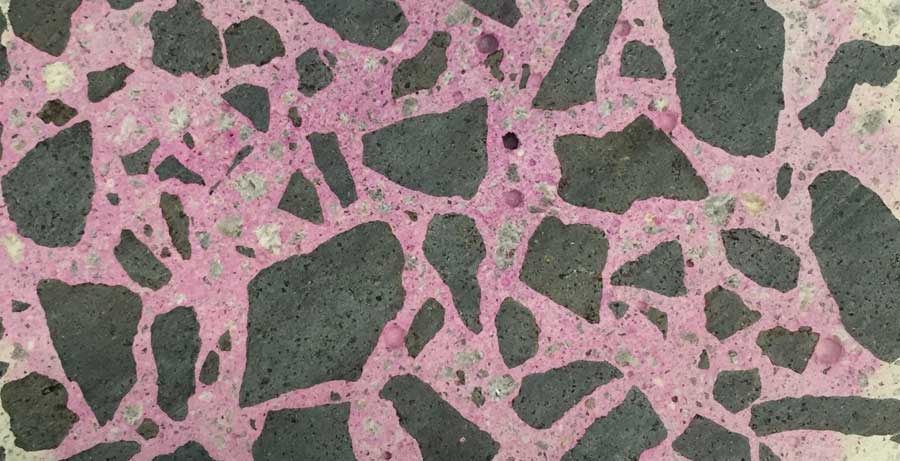

Alkali activated materials (AAM)

Alkali activated materials (AAM) show amazing durability properties. AAM exhibit superior performance to Portland cement concrete (OPCC) in a variety of applications and the GMPG ensure better long-term durability in this material. The fundamental research and insight gained from these research efforts are directly applicable to a wide range of civil-engineering materials. Our effort in this field is associated with international effort of the RILEM-TC 224-AAM, providing guidance and durability methods to assess these new emerging materials. (See Alkali Activated Materials: State-of-the-Art Report, RILEM TC 224-AAM)